In the world of brewing, material choice plays a pivotal role in the efficiency and outcome of the brewing process. Copper and stainless steel are two of the most commonly used materials in brewing equipment. Each offers distinct advantages and potential drawbacks, affecting everything from heat transfer and maintenance to beer quality and environmental impact. This guide provides an in-depth comparison to help brewers decide which material best suits their needs.

Thermal Properties

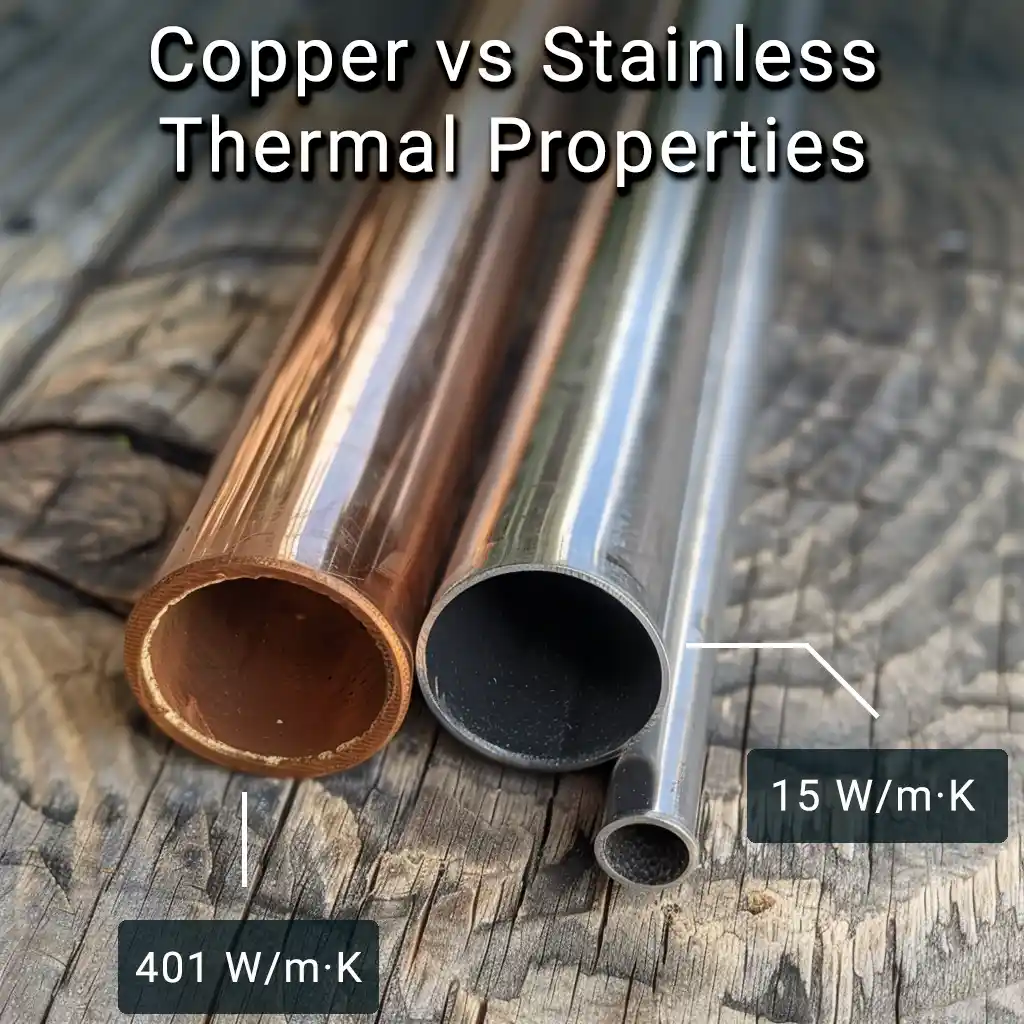

Copper

Copper’s thermal conductivity is among the highest of any commercial metal, approximately 401 W/m·K. This exceptional ability to conduct heat rapidly makes copper ideal for applications where quick thermal response is crucial, such as in wort chillers and heat exchangers. The quick dissipation of heat helps in rapidly cooling the wort, a critical step to avoid prolonged exposure to temperatures that can favor bacterial growth and negatively affect the final quality of the beer. Moreover, copper’s high thermal conductivity ensures more uniform heat distribution, preventing hotspots that could lead to uneven cooling.

Stainless Steel

Although stainless steel’s thermal conductivity is much lower than copper’s, measuring around 15 W/m·K, it offers advantages in specific brewing contexts. The lower thermal conductivity of stainless steel means that temperature changes occur more gradually, which can be advantageous when slow temperature adjustments are necessary to prevent thermal shock to yeast or other sensitive ingredients during the brewing process. However, the slower rate of heat transfer can be a drawback in processes that require rapid cooling or heating, as it may extend the duration of the brewing cycle and increase energy consumption.

Durability and Maintenance

Copper

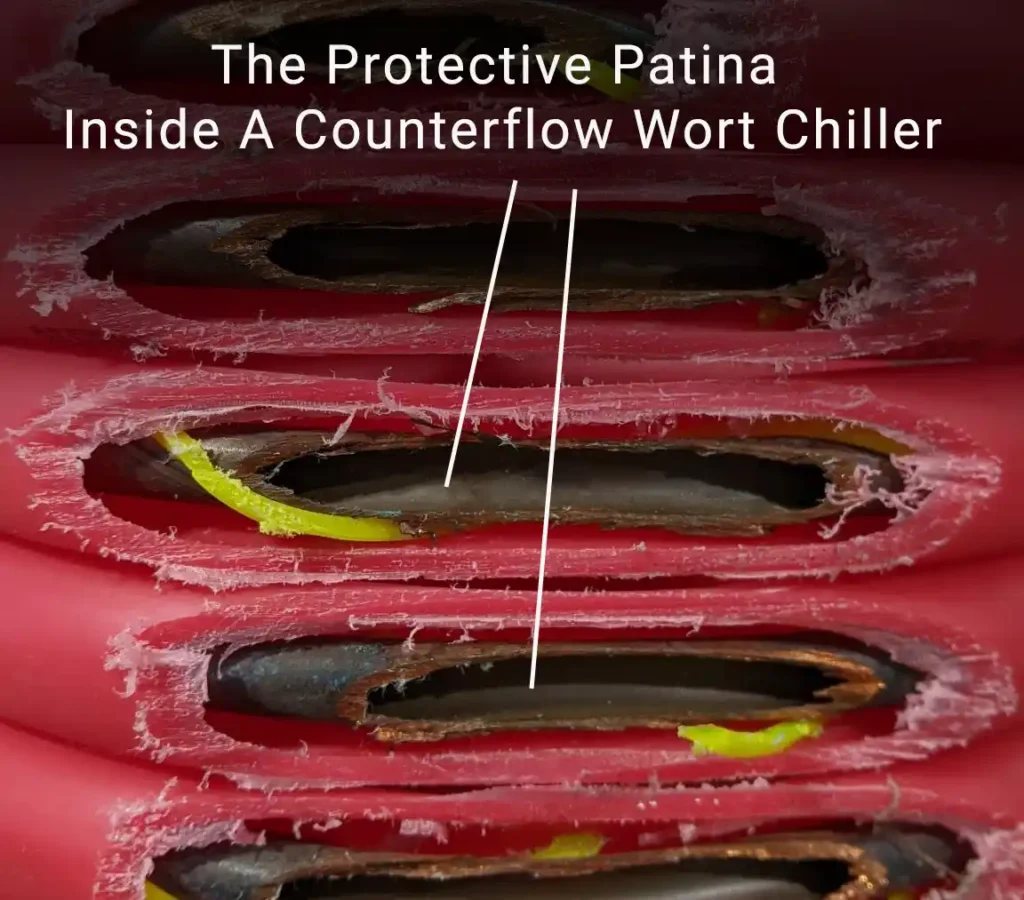

While copper is highly effective in heat transfer applications, making it ideal for wort chilling, its interaction with the brewing environment underscores the importance of maintenance for durability. Over time, copper naturally develops a patina, a layer of tarnish primarily composed of copper oxide. This patina is beneficial, as it stabilizes the copper, making it less reactive in the acidic brewing environment. This tarnish layer not only enhances the durability of copper equipment by protecting it against faster degradation but also ensures consistent performance by maintaining its thermal conductivity.

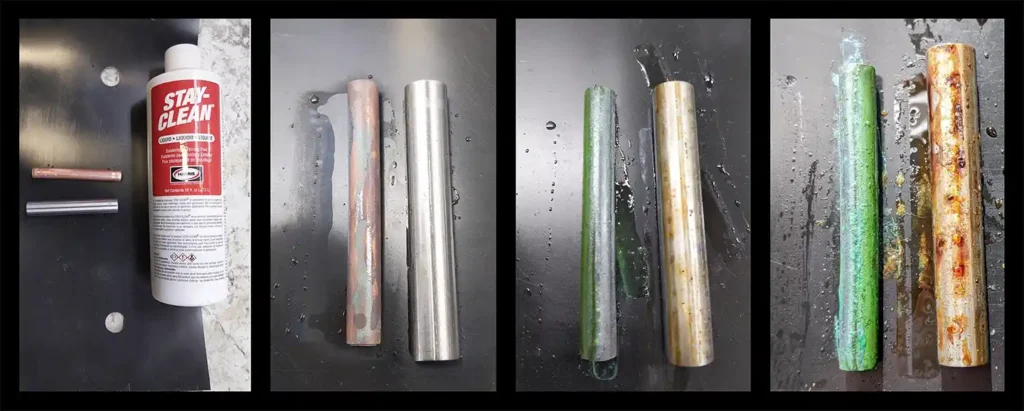

Despite the protective nature of the patina, copper equipment can potentially develop verdigris—the blue or green corrosion that occurs under specific conditions involving exposure to oxygen, carbon dioxide, and moisture. Such corrosion is rare in brewing settings where equipment is well-maintained but could occur if the equipment is improperly stored or neglected. To prevent verdigris and maintain the integrity and functionality of copper brewing equipment, brewers should adhere to a routine maintenance schedule:

- Cleaning: After each use, copper should be cleaned to remove any residues that might contribute to corrosion. Neutral pH cleaners are preferred to avoid enhancing the acidic conditions that promote corrosion.

- Drying: Copper equipment should be thoroughly dried after cleaning to prevent verdigris, which thrives in moist environments.

- Regular Inspections: Periodic inspections will help identify the early formation of unwanted corrosion or damage to the patina, allowing for timely interventions.

By following these maintenance practices, brewers can effectively utilize copper’s excellent thermal properties for efficient wort chilling while minimizing the risks associated with corrosion. This routine care ensures that copper equipment remains durable and continues to perform optimally in the brewing process.

Stainless Steel

Stainless steel is celebrated for its exceptional durability and resistance to corrosion, which makes it ideally suited for the rigorous demands of brewing equipment. Its inherent resilience to acidic and caustic environments ensures that it can withstand the conditions typically found in breweries without deteriorating. Stainless steel’s major advantage is its chromium content, which helps form a passive layer of chromium oxide on the surface. This layer protects the steel from various forms of corrosion and is self-repairing if damaged, thereby extending the equipment’s lifespan. Unlike other metals that may degrade or tarnish, stainless steel maintains its integrity over long periods, even under heavy use. This makes it an excellent choice for brewers seeking long-term reliability without frequent replacements.

Maintenance

- Low Maintenance Requirements: Stainless steel’s need for maintenance is minimal compared to materials like copper. It does not require passivation to stay resistant to corrosion, and its smooth, non-porous surface is easy to clean.

- Cleaning Routine: Routine maintenance typically involves simple cleaning with mild detergents and water, which is sufficient to keep stainless steel brewing equipment in excellent condition. This ease of maintenance not only saves time but also reduces the long-term cost associated with upkeep.

Corrosion Resistance

Enhanced Durability of Stainless Steel

Stainless steel’s alloy composition, including chromium, nickel, and molybdenum, offers excellent corrosion resistance. The chromium content forms a passive layer of chromium oxide on the surface, which protects the steel from oxidation and enhances durability, making it a reliable choice for long-term use in brewing. This corrosion-resistant characteristic ensures that stainless steel equipment remains robust and low-maintenance, even in the acidic environments typical of brewing operations.

Benefits of Copper

Copper, while known for its susceptibility to corrosion, offers unique advantages in the context of wort chilling. The natural patina that forms on copper, primarily composed of copper oxide, serves as a protective layer that significantly reduces the metal’s reactivity. This layer is particularly beneficial in brewing applications as it stabilizes the copper, making it less likely to dissolve into the wort. This characteristic not only maintains the quality and safety of the beer but also enhances the durability of the chiller. Copper’s high thermal conductivity ensures superior performance in rapidly reducing wort temperatures, which is critical for brewing efficiency and quality.

Routine maintenance of copper wort chillers is simple and effective. Regular cleaning, flushing, or rinsing after use is typically sufficient to maintain their condition and prevent any issues related to corrosion. As long as these basic cleaning steps are followed, brewers will likely never face significant problems with their copper chillers. This ease of maintenance, combined with copper’s excellent heat transfer capabilities, makes copper wort chillers an excellent choice for brewers who value efficiency and performance in their cooling process.

Heat Transfer Efficiency / Cooling Efficiency

Rapid Cooling with Copper

Copper’s high thermal conductivity, approximately 401 W/m·K, significantly enhances its ability to both heat up and cool down rapidly. This property is particularly valuable in brewing, where reducing the wort temperature swiftly from boiling to yeast-pitching levels is crucial. Rapid cooling minimizes the time the wort spends in the temperature “danger zone” where bacterial growth is most likely. By quickly bringing the wort to a safe temperature, copper helps achieve optimal pitch temps more quickly and fosters a better environment for your initial pitch. Additionally, rapid cooling is important for the effective formation of the “cold break,” which involves the precipitation of proteins and other solids crucial for clarity and stability in the final product.

Slower Cooling with Stainless Steel

Stainless steel’s thermal conductivity is significantly lower, around 15 W/m·K, which means that it cools wort more gradually. This slower rate of heat transfer can extend the cooling process, which might not be ideal in larger-scale or professional brewing settings where time efficiency and minimizing contamination risks are crucial. However, the gradual reduction in temperature can be managed effectively to ensure your wort is cooled sufficiently for pitching your yeast.

Implications During The Chill

In practice, the choice between copper and stainless steel chillers often comes down to the specific needs of the brewing operation. Copper is generally preferred where speed and efficiency in cooling are paramount, especially in settings where quick throughput and minimizing bacterial risks are crucial. On the other hand, stainless steel might be chosen for its durability and lower maintenance needs, even though its slower cooling rate requires careful management to avoid potential issues with microbial stability.

Both materials have their advantages in the brewing industry, and the choice between them should consider factors like maintenance requirements, durability, and the specific needs of the professional or home brewing operation.

Quantitative Comparison

Cooling Times

To quantify the difference, if a typical copper immersion chiller can cool a batch of wort from boiling down to yeast pitching temperature in about 20 minutes (our does it in less than 5), a similar stainless steel chiller might take 30 to 40 minutes to achieve the same temperature drop. This efficiency can significantly affect the overall brewing schedule and productivity, especially in larger or more time-sensitive brewing operations.

Environmental and Sustainability Issues

Copper

Copper’s environmental impact is twofold. While it is highly recyclable, which reduces its overall environmental footprint, the mining and refining processes associated with copper production can be environmentally intensive. Responsible sourcing and recycling are essential to minimize the environmental impact of using copper in brewing equipment.

Stainless Steel

Stainless steel is also highly recyclable, which helps mitigate its environmental impact. Because it is often possible to recycle stainless steel without loss of quality, it offers an environmentally sustainable option for brewers who are concerned about the lifecycle impact of their equipment choices.

Cost Considerations

Copper

When considering the cost of copper wort chillers, it’s important to look beyond the initial purchase price. Copper’s superior thermal properties can offer significant benefits in brewing efficiency, but these come with considerations of lifetime expenses due to maintenance and potential replacements.

- Initial Investment: Copper is typically more expensive to purchase than stainless steel. This higher cost reflects its excellent thermal conductivity and efficiency in quickly cooling wort, which can significantly enhance brewing operations.

- Maintenance Costs: Copper requires regular maintenance to prevent corrosion and maintain its thermal efficiency. The need for routine cleaning with specific products, potential passivation, and the occasional replacement of parts affected by verdigris (when not maintained) or other corrosion forms can add to the total cost of ownership.

- Long-Term Considerations: Despite the higher ongoing costs, the investment in copper can be justified by the increased brewing efficiency and the potential for improved beer quality. However, brewers need to balance these benefits with the maintenance and care required to optimize the lifespan of their copper equipment.

Stainless Steel

Stainless steel offers a different value proposition. Its lower initial cost and reduced maintenance demands make it appealing, particularly for operations where budget and ease of long-term maintenance are significant concerns.

- Upfront Costs: Generally lower than copper, the initial price of stainless steel wort chillers makes them accessible for a wide range of brewing operations, from small craft breweries to large commercial facilities.

- Maintenance and Durability: The inherent corrosion resistance of stainless steel reduces the need for frequent maintenance, saving on the costs of cleaning supplies, labor, and downtime. Stainless steel does not require passivation to maintain its corrosion resistance, which further reduces long-term care expenses.

- Cost-Effectiveness Over Time: The durability and low maintenance requirements of stainless steel often result in a lower overall cost throughout the equipment’s lifespan. This makes it an economically sound choice for breweries that prioritize long-term budget management without compromising on the quality and consistency of the brewing process.

Comparative Summary

Both materials offer distinct economic advantages dependent on the specific needs and capacities of the brewing operation. Copper, with its high efficiency in heat transfer, may lead to greater upfront and maintenance costs but offers benefits in brewing speed and quality that can justify the investment for many brewers. On the other hand, stainless steel’s lower initial cost and minimal maintenance demands make it a cost-effective option for those looking to minimize long-term operational costs. Brewers must weigh these factors carefully to choose the material that best aligns with their operational goals and financial constraints.

Impact on Beer Quality

Copper

Copper is valued in brewing not only for its thermal properties but also for its beneficial effects on beer quality. The material’s natural interaction with wort plays a crucial role in the chemistry of brewing.

- Enhancing Flavor Clarity: Copper can play a role in the reduction of sulfur compounds during the brewing process. These compounds can cause off-flavors, so their reduction helps in improving the overall flavor clarity and stability of the beer.

- Careful Copper Management: While copper’s benefits are considerable, it is essential to manage its usage appropriately within the brewing process. Regular monitoring and maintaining proper cleaning protocols are crucial to harness copper’s benefits without compromising the beer’s taste and quality.

Stainless Steel

Stainless steel is favored in many brewing applications for its chemical inertness, which has distinct advantages for maintaining beer quality throughout the brewing and storage processes.

- Preserving Beer Integrity: The inert nature of stainless steel means it does not introduce any foreign flavors or substances into the beer, maintaining the integrity of the original flavor profile intended by the brewer.

- Consistency Across Batches: Stainless steel ensures that each batch of beer can be produced with consistent quality. Its non-reactive properties prevent any variation in taste that might occur due to material interaction, which is especially important for breweries that pride themselves on consistent product quality.

Conclusion

The choice between copper and stainless steel in brewing depends on a balance of factors including cost, specific brewing needs, maintenance capacity, and environmental considerations. Copper, with its excellent thermal properties, suits components requiring rapid temperature control, while stainless steel is ideal for longer-term beer contact applications, offering durability and maintenance ease. Often, the best approach is a combination of both materials, utilizing each where it performs best to optimize brewing efficiency and enhance beer quality.